Foam Equipment

Advanced fire suppression – Sparkline Fire's foam systems offer rapid response and effective containment of flammable liquid fires.

Foam Firefighting Equipment

Designed for high-risk environments, our foam systems deliver rapid control of Class B flammable liquid fires.

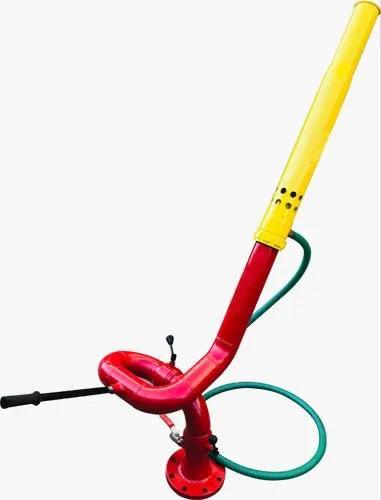

Foam Monitor

Foam Monitors are high-capacity devices used to deliver large volumes of water or foam in industrial fire protection systems. Designed for remote or manual operation, they are ideal for covering large areas such as fuel farms, tank terminals, and chemical plants.

Key Features

Product Images

Most Effective For

Technical Specifications

| Material | Stainless Steel / Aluminium Alloy |

|---|---|

| Flow Rate | 2250 – 4500 LPM |

| Operating Pressure | 7 to 10 bar |

| Rotation | Horizontal 360°, Vertical ±75° |

| Control | Manual Lever / Remote Gear |

| Inlet Size | 63 mm / 75 mm |

| Finish | Red Epoxy Coated |

Ideal Use

Used in high-risk fire zones where large-scale foam discharge is critical.

Refineries

Tank Terminals

Chemical Units

Emergency Zones

Foam Branch Pipe

The Foam Branch Pipe is a lightweight and easy-to-handle nozzle that produces high-expansion foam by mixing foam concentrate, water, and air. It is specifically engineered for use in flammable liquid fire scenarios, providing effective blanketing and smothering capabilities. Widely used in oil depots, chemical facilities, and fuel terminals.

Key Features

Product Images

Most Effective For

Liquids

Technical Specifications

| Body Material | Aluminium Alloy / Stainless Steel |

|---|---|

| Foam Expansion | Medium to High |

| Inlet Connection | Instantaneous Coupling (63 mm) |

| Flow Rate | 225 to 450 LPM |

| Working Pressure | 7 to 10 bar |

| Application | Foam Suppression Systems |

| Weight | 2.5 – 4.5 kg (approx.) |

Ideal Use

Fuel Terminals, Oil Depots, Aircraft Hangars, Chemical Storage Yards

Fuel Zones

Depots

Chemicals

Hangars

Foam Concentrate Tank

Engineered to store fire-fighting foam concentrate for medium to high-volume suppression systems, the Foam Concentrate Tank ensures consistent foam flow during fire emergencies. It integrates seamlessly with foam proportioners and discharge devices to maintain system efficiency and reliability.

Key Features

Most Effective For

Storage

Fire Systems

Zones

Technical Specifications

| Material | Stainless Steel / Mild Steel |

|---|---|

| Capacity Range | 100 L to 10,000 L |

| Orientation | Horizontal / Vertical |

| Coating | Epoxy / Internal Anti-Corrosive |

| Connection Type | Flanged / Threaded |

| Operating Pressure | Up to 12 bar |

| Inspection Port | Yes (with manhole access) |

| Accessories | Level gauge, vent, drain valve, pressure relief |

Ideal Use

Industrial Plants, Refineries, Airports, Chemical Warehouses

Industry

Oil & Gas

Airports

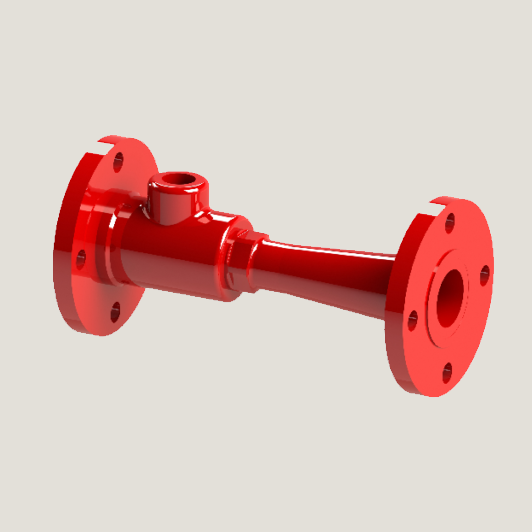

Inline Foam Inductor

The Inline Foam Inductor is a compact, portable unit used to proportion foam concentrate with water at precise preset ratios. Ideal for hydrocarbon and aviation fuel fires, it ensures effective foam generation by connecting directly between the hose line and nozzle.

Key Features

Most Effective For

Fires

Fuels

Spills

Liquids

Technical Specifications

| Body Material | Brass / Stainless Steel |

|---|---|

| Foam Concentration | 3% or 6% |

| Inlet / Outlet | 2.5" BSP / Instantaneous Coupling |

| Flow Rate | 225 to 450 LPM |

| Working Pressure | 7 to 10 bar |

| Weight | 3 – 6 kg (approx.) |

| Usage | Inline hose-nozzle integration |

Ideal Use

Oil Refineries, Airports, Industrial Fire Brigades, Petroleum Facilities

Fuel Zones

Airports

Fire Brigades

Industrial